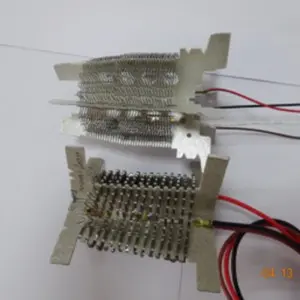

Hair dryer heating element Mica heating core Electric heat resistance

Electric hair dryer heating elements are make of mica and OCR25AL5 or Ni80Cr20 heating wires, all material are comply with ROHS certificate. It is including AC and DC motor hair dryer heating elements.The hair dryer power can be done from 50W to 3000W.Any size can be customized. The fuse and thermostat have UL/VDE certificate. Some appliance please see the below:

- Hair Drying and Styling: The most common use is in personal care devices such as hair dryers. The heating element, usually made of materials like nichrome wire, quickly heats up when electricity passes through it. This heated element then warms the air that flows over it, producing hot air that dries and styles hair.

- Portable Heaters : Similar technology can be adapted for portable heaters used in small spaces. These devices can provide quick and targeted warmth, making them ideal for temporary heating solutions.

- Industrial Drying Applications: In industrial settings, similar heating elements are used in drying processes where rapid evaporation of moisture is required. This can include paint drying, adhesive curing, or drying out parts after cleaning. 4. **Medical Devices: Some medical devices also utilize heating elements for therapeutic purposes, such as providing warm air for respiratory treatments or for warming blankets in hospitals.

- Laboratory Equipment: Heating elements are used in various laboratory equipment, including incubators and drying ovens, to maintain precise temperature control during experiments or sample preparation.

- Automotive Industry: Within the automotive industry, heating elements can be found in car defrosters and seat heaters, contributing to passenger comfort and safety by clearing windshields and providing warmth.

The core technology of heating elements in electric hair dryers can thus be leveraged across multiple industries and applications, emphasizing their versatility and importance in both everyday and specialized uses.