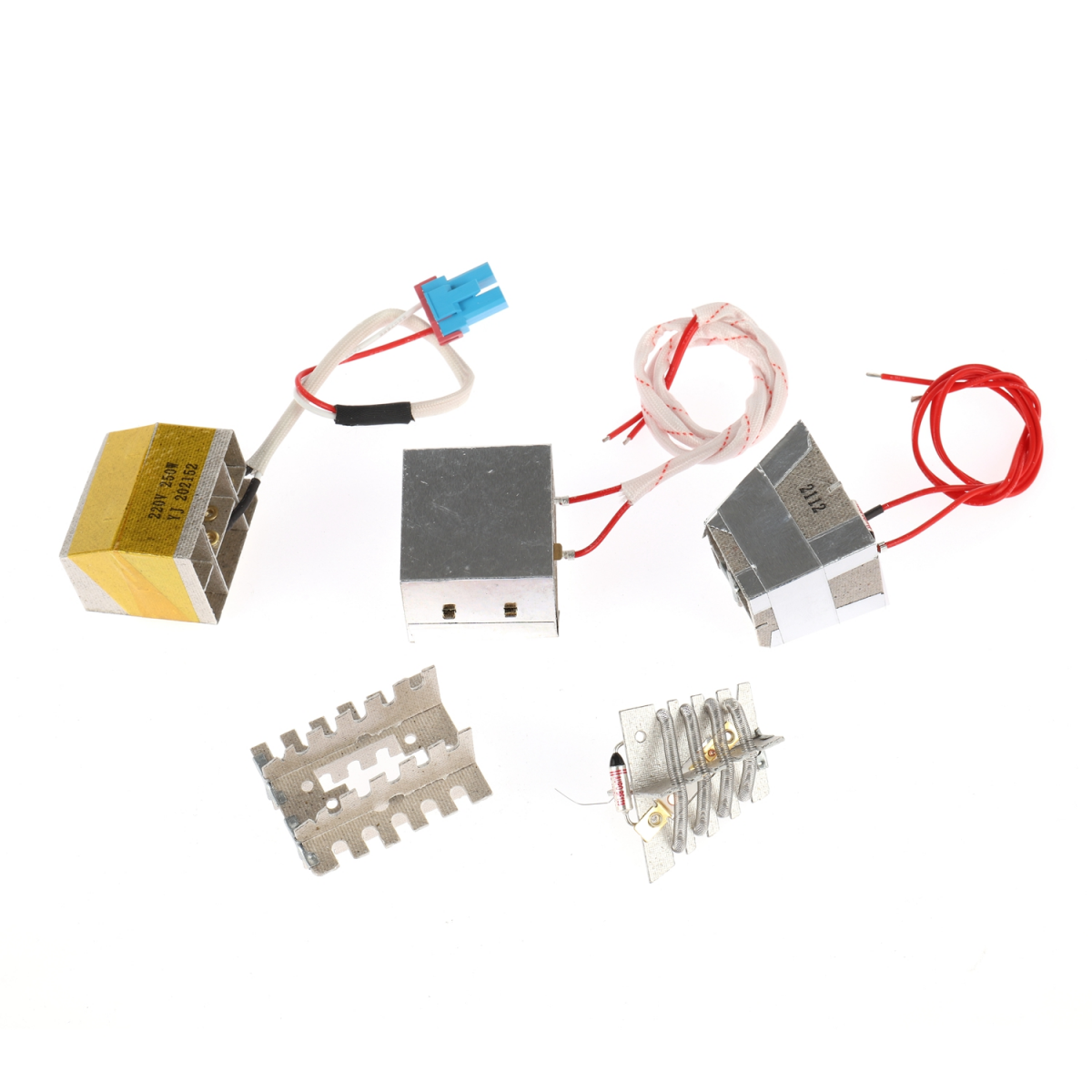

Electric heaters come in various forms and configurations to adapt to specific applications. The following are the most common Electric heaters and their applications.

Air Heater: As the name suggests, this type of heater is used to heat the flowing air. The air heater basically shapes and distributes resistance wires on the air circulation surface. The applications of air treatment heaters include intelligent toilet drying heaters, heaters, hair dryers, dehumidifiers, etc.

Tubular Heater:

Tubular heater is composed of metal tubes, resistance wires, and crystalline magnesium oxide powder. After being electrified, the heat generated by the resistance wire diffuses to the surface of the metal tube through magnesium powder, and then transfers to the heated part or air to achieve the purpose of heating. The applications of tubular heaters include irons, fryers, air fryers, ovens, etc.

Belt type Heater:

This type of heater is a circular strip that is fixed around the heating components using nuts, etc. Within the band, the heater is a thin resistance wire or strip, usually wrapped around a mica layer of insulation. The shell is made of metal and aluminum sheets. The advantage of using a belt heater is that it can indirectly heat the fluid inside the container, which means that the heater will not be subjected to any chemical attack from the process fluid. The applications of belt heaters include water dispensers, cooking pots, electric rice cookers, injection molding machines, etc.

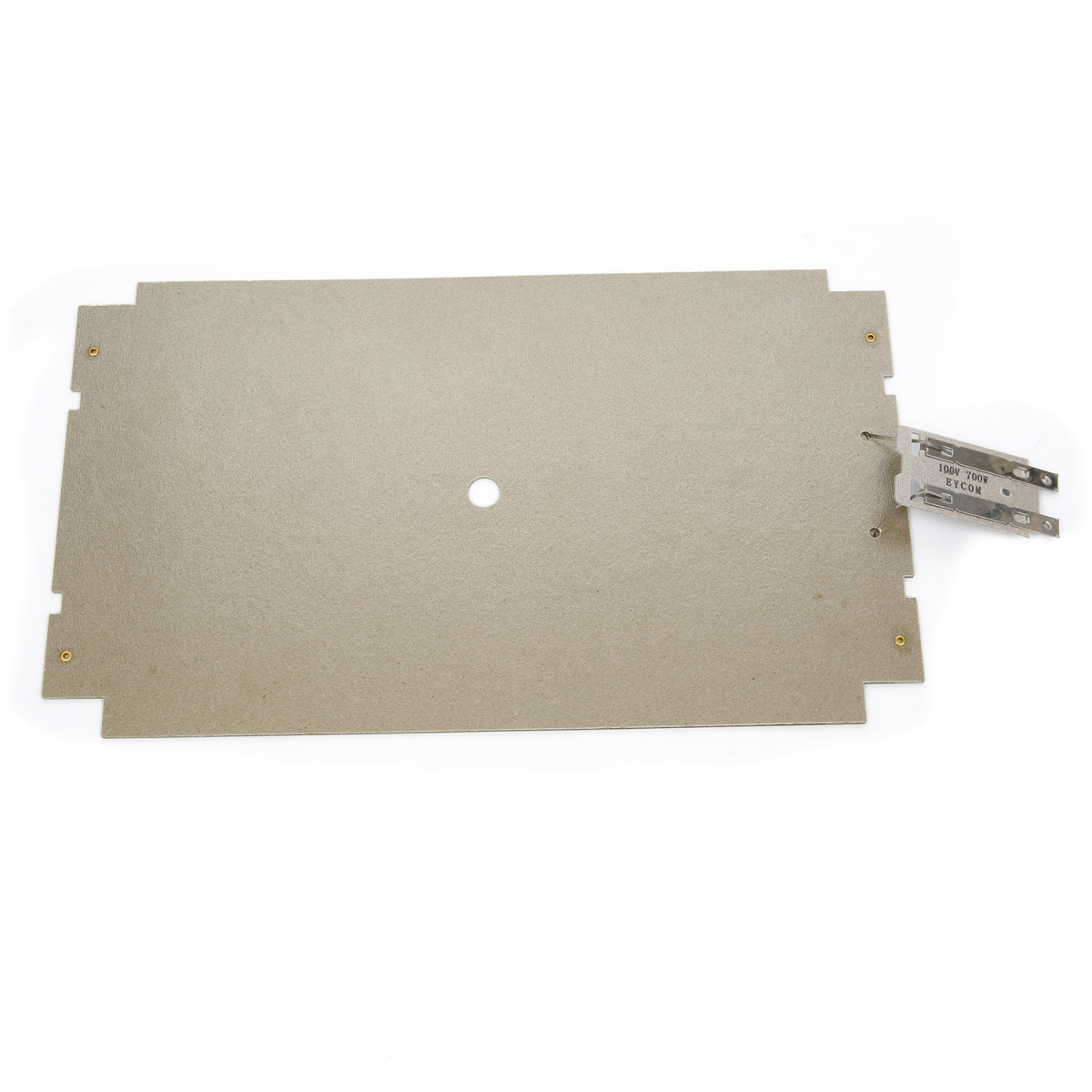

Sheet Heater: This type of heater is flat and fixed on the surface to be heated. Structurally, mica wrapped heating wires are used, aluminum foil hot melt heating wires are also used, and the heating wires are etched and bonded to insulation materials. The applications of sheet heaters include toilet seats, heating boards, insulation pads, etc.

Customization of heating elements and heaters, consulting services for thermal management solutions: Angela Zhong 13528266612(WeChat) Jean Xie 13631161053(WeChat)

Post time: Sep-19-2023