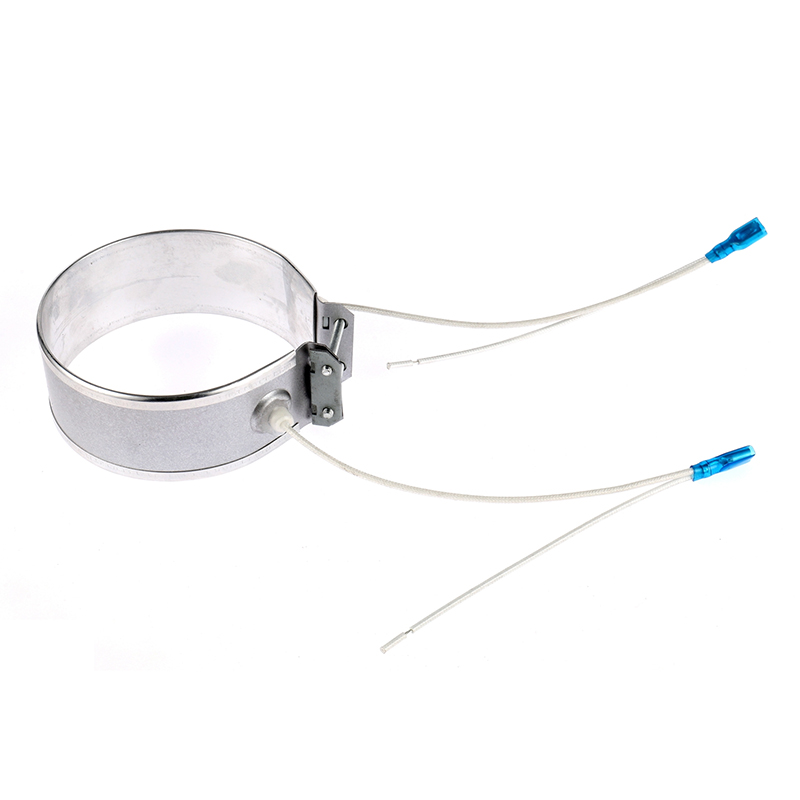

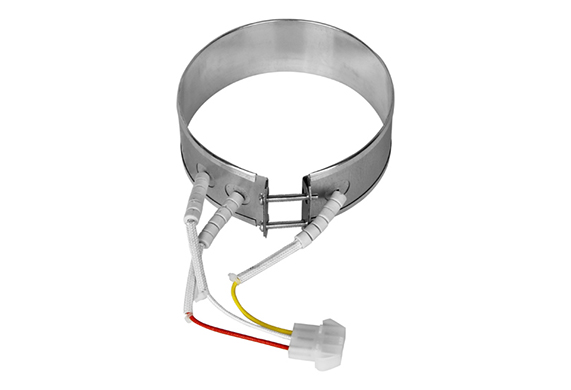

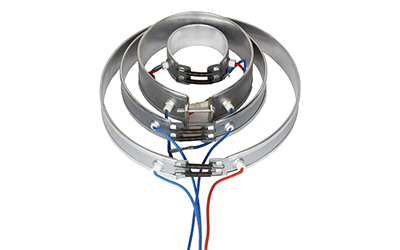

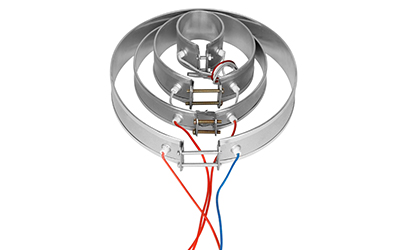

Electric heating element for wax heater

Product Specification

|

MODEL |

FRQ-105 |

|

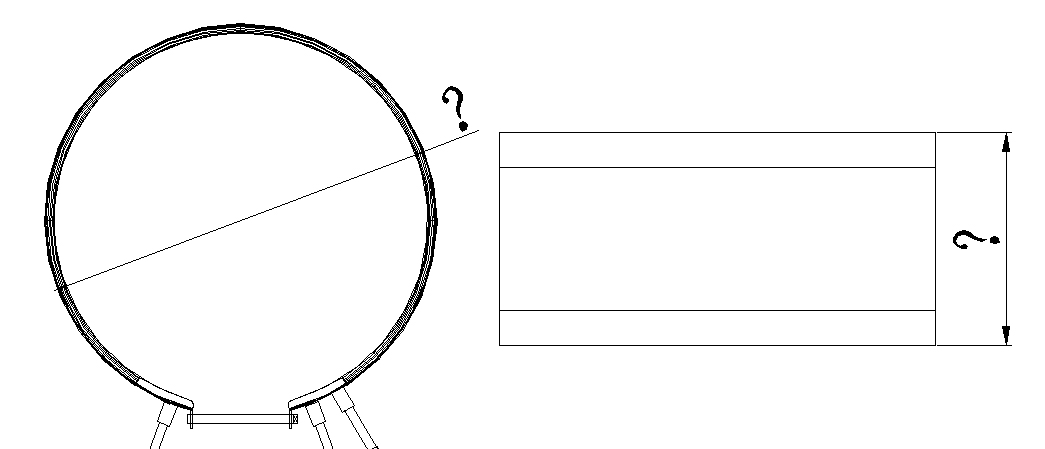

Size |

Φ105*36MM |

|

Voltage |

100V-240V |

|

Power |

100W-500W |

|

Material |

SECC & aluminium plate |

|

Color |

silver |

|

Power line with UL certificate |

|

|

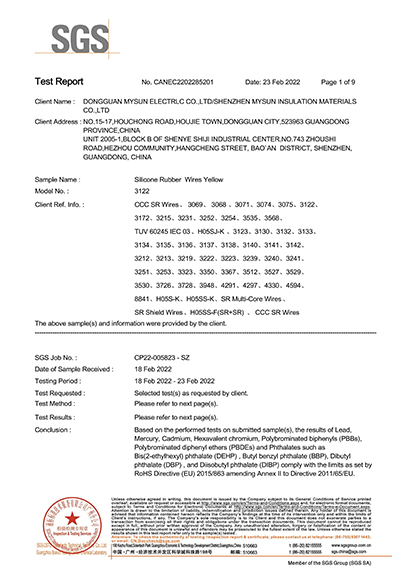

All material with ROHS standard |

|

|

Packing |

180pcs/ctn |

|

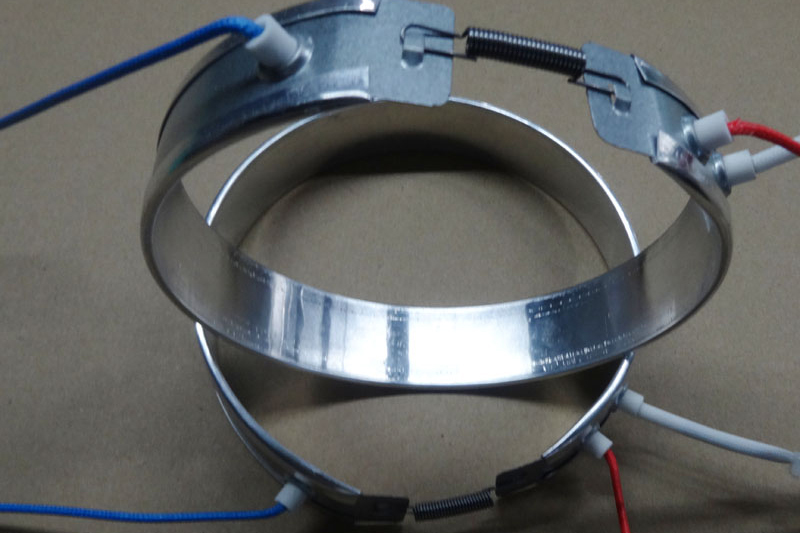

Apply to |

slow cooker, wax heater |

|

Any size can be made same as your requirements. |

|

|

MOQ |

500 pcs |

|

FOB |

USD0.86/PC |

|

FOB ZHONGSHAN or GUANGZHOU |

|

|

PAYMENT |

T/T, L/C |

|

Output |

2500PCS/day |

|

Lead time |

25days |

|

Package |

50pcs/ctn, |

|

66*36*35cm |

|

|

20'container |

10000pcs |

Product Application

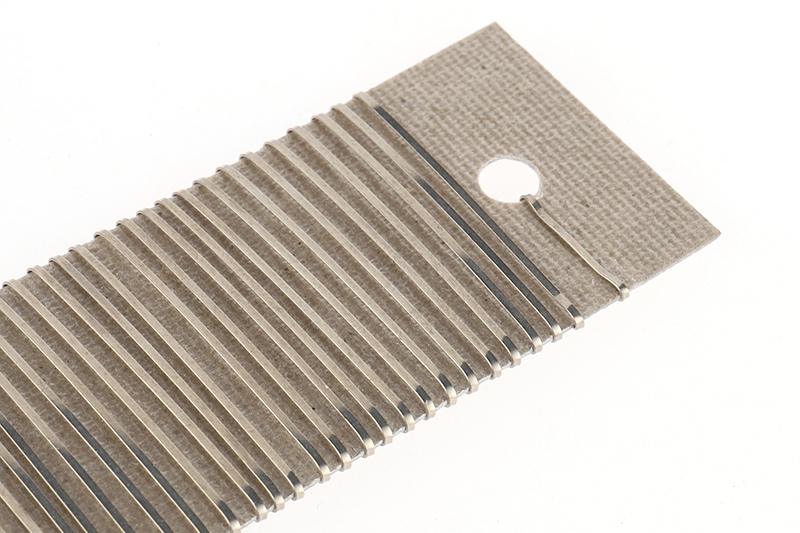

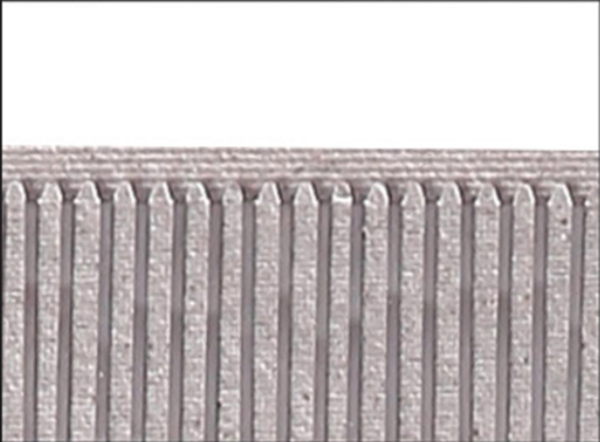

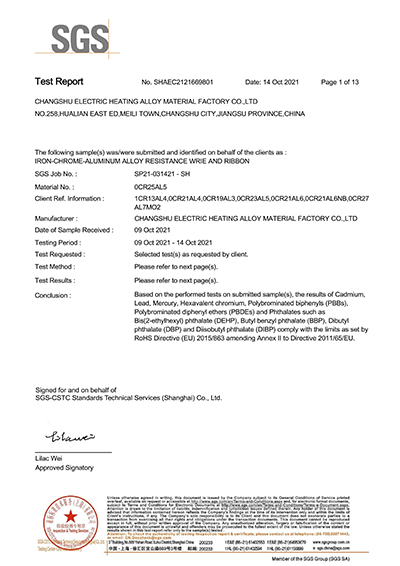

1.Electric band heater are make of mica and OCR25AL5 or Ni80Cr20 heating wires, all material are comply with ROHS certificate.

2.Mica band heaters are commonly used in various industrial applications for heating cylindrical or flat surfaces. Some of the common applications of mica band heaters include, 1. Plastic injection molding machines, Mica band heaters are used to heat the barrels of plastic injection molding machines, which melt the plastic resin before it is injected into a mold.

3. Extrusion machines: Mica band heaters are used to heat the barrels of extrusion machines, which melt and shape plastic or metal materials into various profiles.

4. Blow molding machines: Mica band heaters are used to heat the molds in blow molding machines, which shape molten plastic into hollow objects, such as bottles or containers.

5. Packaging and sealing equipment: Mica band heaters are used in packaging machines, such as heat sealers, to provide controlled and uniform heat for sealing packaging materials, such as plastic films or bags.

6. Food processing equipment: Mica band heaters are used in food processing equipment, such as ovens, to provide heat for cooking, drying, or to maintain specific temperature conditions.

7. Heating and drying equipment: Mica band heaters are used in various heating and drying applications, such as in industrial ovens, drying tunnels, or heat treating processes.

8. Laboratory equipment: Mica band heaters can be used in laboratory equipment, such as distillation units, where controlled heating is required for specific experiments or processes.

9. Household appliances, such as water fountain, slow cooker, oil press machine, wax heater etc. These are just a few examples of the applications of mica band heaters. They can be customized and used in various other household appliances, industries and equipment where controlled and efficient heating is required.

Eycom has a high precision testing equipment laboratory, production process needs to go through a number of tests. Its' standardized process, professional testing, to ensure the quality of products.

Products in the world has always maintained good competitiveness.

It has become the strategic partner of famous domestic, foreign household appliances and bathroom brands. Eycom is the preferred brand for electric heating elements and industrial equipments.

FAQ

Q 1. Are you factory?

A. Yes. Welcome to visit our factory and cooperation with us.

Q 2. Can I get the free sample?

A. Sure, 5pcs of samples are free for you, you just arrange the delivery cost to your country.

Q 3.What is your working time?

A. Our working is from 7:30 to 11:30 AM, 13:30 to 17:30 PM, but customer service will be online 24 hours for you, you can consult any questions at any time, thank you.

Q 4. How many employees do you have in your factgory?

A. We have 136 production staffs and 16 office staffs.

Q 5. how can we guarantee quality?

A. We test each product before package to ensure all the products are well with good package. Before making mass production, we have QC diagram and Working Instruction to ensure each process is correct.

Q 6. what services can we provide?

Accepted Delivery Terms: FOB, CIF, EXW.

Q7. Accepted Payment Currency: USD, EUR, JPY, CAD, AUD, GBP, CNY;

Q8. Accepted Payment Type: T/T, L/C, D/P D/A, MoneyGram, Credit Card, PayPal, Western Union, Escrow;

Q9. Language Spoken: English, Chinese.

Production Process

Application Scenarios

Optional Parameters

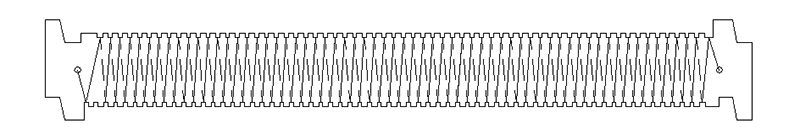

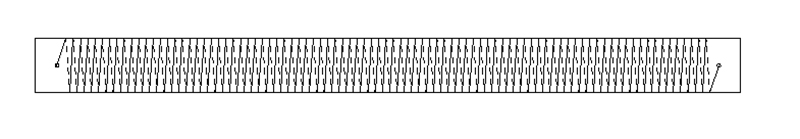

Winding Mode

Use sawtooth to limit the position of heating wire, and heat evenly.

Effective production price advantage and greater daily supply.

Optional Parts

Materials Used

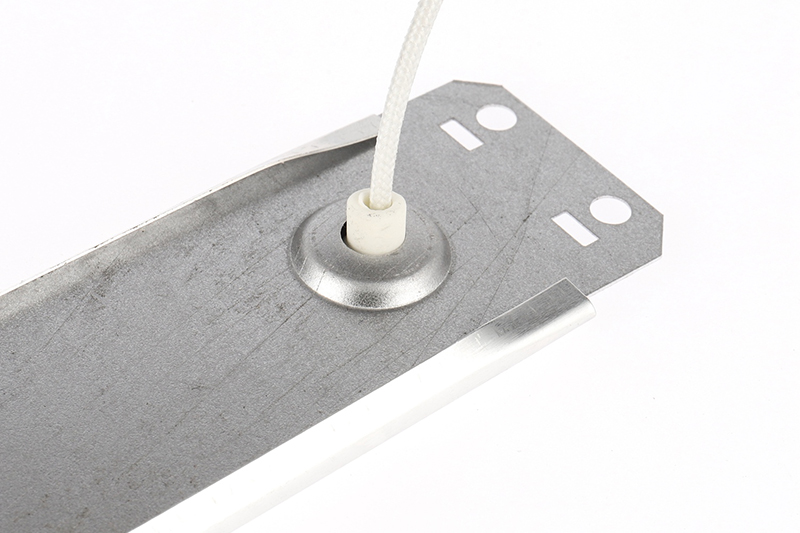

Use spring:The selection of spring can save manpower.

Use silicone:High cost performance.

Use steel: Good fixed effect.

Use screw:The selection of screw can tighter.

Use ceramic:Long life,time.

Use aluminum:Good appearance.

Our Advantages

Heating Materials

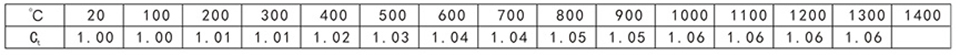

OCr25Al5:

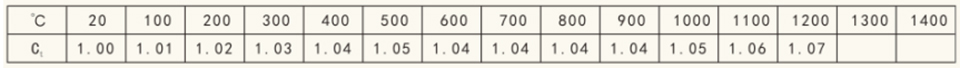

Cr20Ni80:

Using stable heating materials, the error between cold state and hot state is small.

ODM/OEM

We can design and make samples according to customer needs.

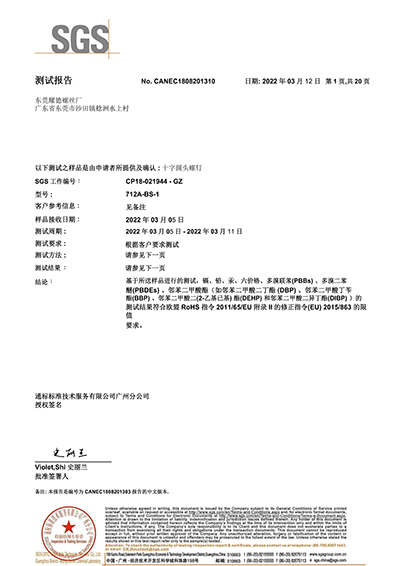

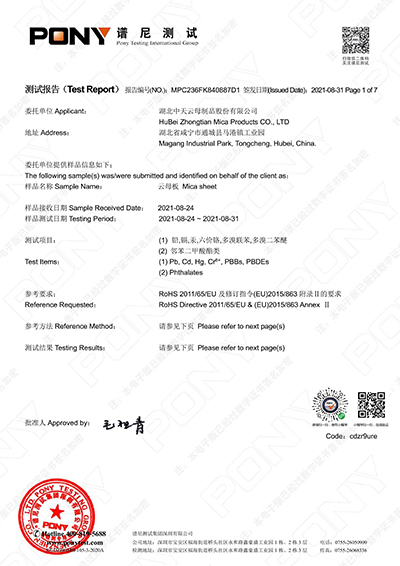

Our Certificate

All materials we use have RoHS certificates.